Optimization of the cylindrical sieves for separating threshed rice mixture using EDEM

Keywords:

cylindrical sieve, threshed rice mixture, discrete element method, separation, rice, optimizationAbstract

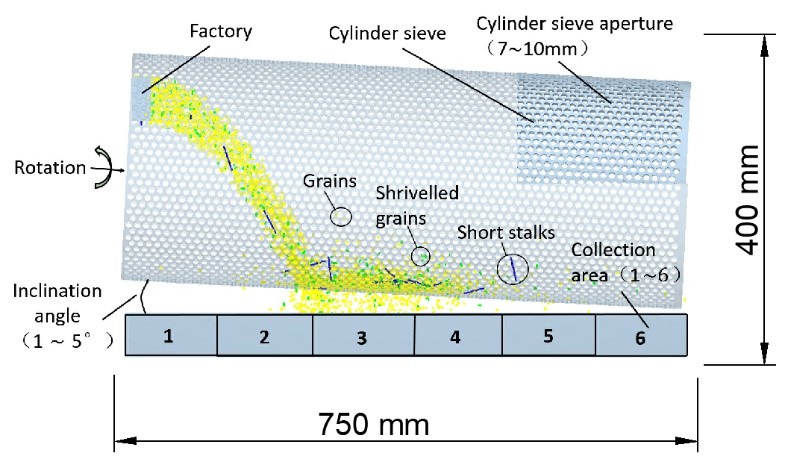

The design of the cylindrical sieve equipment used for the screening and separation of agricultural granular materials is mainly through the experimental method, which has the disadvantages of a long development cycle and high cost. To solve this problem, the discrete element method (DEM) was utilized to accurately build the particle models of threshed rice components (grains, shriveled grains, and short stalks), and simulated the separation of grains from the mixture in a cylindrical sieve. The influences of rotational speed (A), cylindrical sieve diameter (B), cylindrical sieve aperture (C), and inclinational angle (D) on screening cleaning rate, screening loss rate, and screening efficiency were investigated. Meanwhile, the optimal parameters of the cylindrical sieve were obtained using a central composite design (CCD) under response surface methodology (RSM). The results of CCD showed that the quadratic multinomial model is credible and revealed that the cylindrical sieve aperture has a significant impact on the screening characteristics. It is predicted that the optimal values for screening cleaning rate, loss rate, and efficiency were 97.84%, 0.27%, and 85.38%, respectively, while A, B, C, and D were 23.6 r/min, 297 mm, 8.7 mm, and 2°, respectively. The experimental results using a real threshed rice mixture were found to be in good agreement with the optimal simulation results. This study proved a reliable research method and provides a design reference for the cylinder sieving systems for threshed rice or separation of other bulk material. Keywords: cylindrical sieve, threshed rice mixture, discrete element method, separation, rice, optimization DOI: 10.25165/j.ijabe.20221502.5150 Citation: Yuan J B, Wang J F, Li H, Qi X D, Wang Y J, Li C. Optimization of the cylindrical sieves for separating threshed rice mixture using EDEM. Int J Agric & Biol Eng, 2022; 15(2): 236–247.References

Liang Y. Brief report on the forecast of world agricultural products supply and demand in 2022. World Agriculture, 2022; 3: 126–131. (in Chinese)

Luo X W, Wang Z M, Zeng S, Zang Y, Yang W W, Zhang M H. Recent advances in mechanized direct seeding technology for rice. Journal of South China Agricultural University, 2019; 40(5): 1–13. (in Chinese)

Bellocq B, Ruiz T, Delaplace G, Duri A, Cuq B. Screening efficiency and rolling effects of a rotating screen drum used to process wet soft agglomerates. Journal of Food Engineering, 2017; 195: 235–246.

Zhang L H, Xue D Q, Ma S B, Fu C G, Hou S L. Reaserch on impurities of the cropstraw and trommel sieve. Acta Energiae Solaris Sinica, 2014; 35(3): 433–438. (in Chinese)

Lyu S W, Shang S Q, Wang D W, He X N, Zhao Z L, Zhang Y D. Design and research of peanut cleaning and sorting machine. Journal of Agricultural Mechanization Research, 2019; 41(9): 71–75. (in Chinese)

Wan X, Shu C, Xu Y, Yuan J, Li H, Liao Q. Design and experiment on cylinder sieve with different rotational speed in cleaning system for rape combine harvesters. Transactions of the CSAE, 2018; 34(14): 27–35. (in Chinese)

Ivanov N M, Fedorenko I Y, Zakharov S E, Sukhoparov A A. Evaluating grain feed at separation by planetary cylindrical sieve with round holes. Sibirskii vestnik sel'skokhozyaistvennoi nauki, 2017; 5(47): 72–79.

Sabashkin V A, Sukhoparov A A, Sinitsyn V A, Zakharov S E. Removing straw impurities from grain heaps by cylindrical sieve. Sibirskii Vestnik Sel'skokhozyaistvennoi Nauki, 2017; 47(5): 80–87.

Ma Z, Li Y M, Xu L Z. Summarize of particle movements research in agricultural engineering realm. Journal of Chinese Agricultural Mechanization, 2013; 2: 22–29. (in Chinese)

Grozubinsky V, Sultanovitch E, Lin I J. Efficiency of solid particle screening as a function of screen slot size, particle size, and duration of screening the theoretical approach. International Journal of Mineral Processing, 1998; 52(4): 261–272.

Cheng J. Discussion on screening efficiency and hole blocking problem of circular vibrating screen. Mining machinery journal, 1988; 2: 58–61.

Nati C, Magagnotti N, Spinelli R. The improvement of hog fuel by removing fines, using a trommel screen. Biomass and Bioenergy, 2015; 75: 155–160.

Lau S T, Cheung W H, Kwong C K, Wan C P, Choy K K H, Leung C C, et al. Removal of batteries from solid waste using trommel separation. Waste Management, 2005; 25(10): 1004–1012.

Xu S. Optimization design on trommel for sieving building sand from iron tailings. Mining & Processing Equipment, 2018; 46(1): 49–52. (in Chinese)

Cundall P A. A computer model for simulating progressive, large-scale

movements in blocky rock systems. In: Proceedings of Symposium of Intrnational Society of Rock Mechanics, Nancy, 1971; 1: 11–18.

Ma Z, Li Y, Xu L. Discrete-element method simulation of agricultural particles' motion in variable-amplitude screen box. Computers and Electronics in Agriculture, 2015; 118: 92–99.

Mustafa U, M F J, Chris S. Three-dimensional discrete element modelling of tillage: Determination of a suitable contact model and parameters for a cohesionless soil. Biosystems Engineering, 2014; 121: 105–117.

Wang D, Servin M, Mickelsson K O. Outlet design optimization based on large-scale nonsmooth DEM simulation. Powder Technology, 2014; 253: 438–443.

Alchikh-Sulaiman B, Alian M, Ein-Mozaffari F, Lohi A, Upreti S R. Using the discrete element method to assess the mixing of polydisperse solid particles in a rotary drum. Particuology, 2016; 25: 133–142.

Ma X D, Guo B J, Li L L. Simulation and experiment study on segregation mechanism of rice from straws under horizontal vibration. Biosystems Engineering, 2019; 186: 1–13.

Xu L Z, Wei C C, Liang Z W, Chai X Y, Li Y M, Liu Q. Development of rapeseed cleaning loss monitoring system and experiments in a combine harvester. Biosystems Engineering, 2019; 178: 118–130.

Wang X, Zhang S, Pan H, Zheng Z, Huang Y, Zhu R. Effect of soil particle size on soil-subsoiler interactions using the discrete element method simulations. Biosystems Engineering, 2019; 182: 138–150.

Lima E, Winkler E L, Tobia D, Troiani H E, Zysler R D, Agostinelli E, et al. Bimagnetic CoO Core/CoFe2O4 shell nanoparticles: Synthesis and magnetic properties. Chemistry of Materials, 2012; 24(3): 512. doi: 10.1021/cm2028959.

Cundall P A, Strack O D L. A discrete numerical model for granular assemblies. Géotechnique, 1979; 1(29): 47–65.

Hu G M. Analysis and simulation of granular system by discrete element method using EDEM. Wuhan: Wuhan University of Technology Press, 2010; 302p. (in Chinese)

Zhou Z Y, Zhu H P, Yu A B, Wright B, Zulli P. Discrete particle simulation of gas-solid flow in a blast furnace. Computers & Chemical Engineering, 2008; 32(8): 1760–1772.

Tsuji Y, Tanaka T, Ishida T. Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technology, 1992; 71(3): 239–250.

Mindlin R D. Compliance of elastic bodies in contact. Journal of Applied Mechanics, 1949; 16(3): 259–268.

Li H, Qian Y, Cao P, Yin W, Dai F, Hu F, et al. Calculation method of surface shape feature of rice seed based on point cloud. Computers and Electronics in Agriculture, 2017; 142: 416–423.

Yuan J B, Li H, Wu C Y, Qi X D, Shi X X, Li C. Study on apace particle modeling of rice grain basis on the Discrete Element Method. Journal of Nanjing Agricultural University, 2018; 41(6): 1151–1158. (in Chinese)

Kruggel-Emden H, Rickelt S, Scherer W V. A study on the validity of the multi-sphere Discrete Element Method. Powder Technology, 2008; 188(2): 153–165.

Józef H, Marek M. Parameters and contact models for DEM simulations of agricultural granular materials: A review. Biosystems Engineering, 2016; 147: 206–225.

Yang S. Research of 4L-80A miniature combine harvester. Master dissertation. Nanjing: Nanjing Agricultural University, 2011; 48p. (in Chinese)

Yuan J B, Wu C Y, Li H, Qi X D, Xiao X X, Shi X X. Determination and analysis of two kinds of threshed rice physical properties in South China. Journal of Agricultural Mechanization Research, 2018; 40(2): 154–159. (in Chinese)

Li H C, Li Y M, Gao F, Zhao Z, Xu L Z. CFD-DEM simulation of material motion in air-and-screen cleaning device. Computers and Electronics in Agriculture, 2012; 88: 111–119.

Yang X L. Study on screen-penerating performance of grains with fifferent material and shape. Master dissertation. Zhengzhou: Zhengzhou University, 2007; 84p. (in Chinese)

Fang L P, Wu B L, Chan J K M, Lo I M C. Lanthanum oxide nanorods for enhanced phosphate removal from sewage: A response surface methodology study. Chemosphere, 2018; 192: 209–216.

GB/T 5262-2008. Measuring method for agricultural machinery testing conditions - General rules. The Standardization Administration of China, 2008. (in Chinese)

Downloads

Published

How to Cite

Issue

Section

License

IJABE is an international peer reviewed, open access journal, adopting Creative Commons Copyright Notices as follows.

Authors who publish with this journal agree to the following terms:

- Authors retain copyright and grant the journal right of first publication with the work simultaneously licensed under a Creative Commons Attribution License that allows others to share the work with an acknowledgement of the work's authorship and initial publication in this journal.

- Authors are able to enter into separate, additional contractual arrangements for the non-exclusive distribution of the journal's published version of the work (e.g., post it to an institutional repository or publish it in a book), with an acknowledgement of its initial publication in this journal.

- Authors are permitted and encouraged to post their work online (e.g., in institutional repositories or on their website) prior to and during the submission process, as it can lead to productive exchanges, as well as earlier and greater citation of published work (See The Effect of Open Access).